Vacuum Tubing and Fittings

Straight or Expanded Ends. Aluminum, Stainless, Carbon, Galvanized. All Gauges.

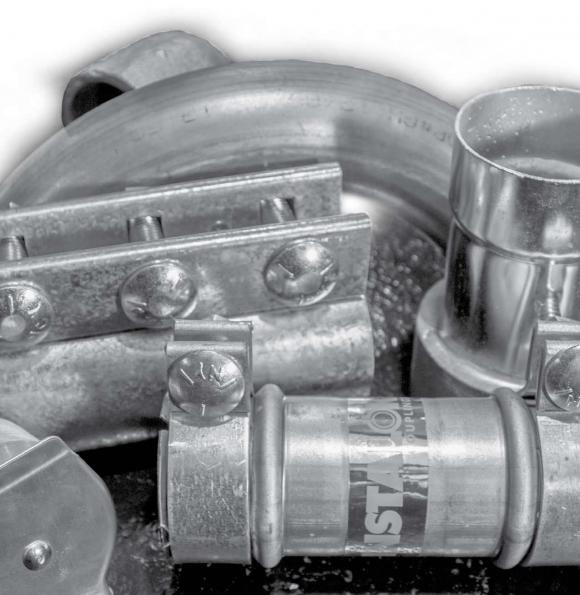

Tubing and Fittings for Central Vacuum Systems

Standard Vacuum Tubing

Our vacuum tubing is typically cut straight, but it can also be cut at an angle or with a laser-cut bevel for high-tolerance projects. The tubing is available in custom lengths. We also have options for ceramic and porcelain lined pipe and fittings.

We provide fast shipping on a wide selection of tubing and ducting, including tubing, pipe, bends, compression couplings, fittings, and installation components. Our standard tube and pipe parts are available in carbon, galvanized, stainless steel, and aluminum. With superior quality and competitive pricing, our components provide the ideal solution.

- 2” to 14” OD

- Wall Thickness: 16, 14, 12, 11 Gauge

- Materials: Carbon, Stainless Steel, Aluminum, Galvanized Steel

- We can provide 1-1/2” to 14” OD. OD

Click THIS-LINK for details

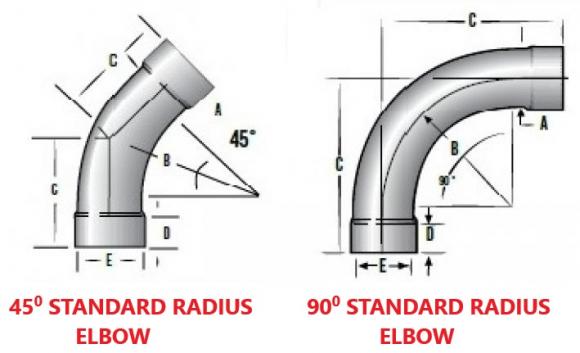

Standard Radius Elbows

- 30° and 60° Elbows available

- 11 Gauge elbows are straight ends only

- Expanded ends through 6" only

- Expanded one side available

- Straight ends available on all sizes

Click THIS-LINK for details

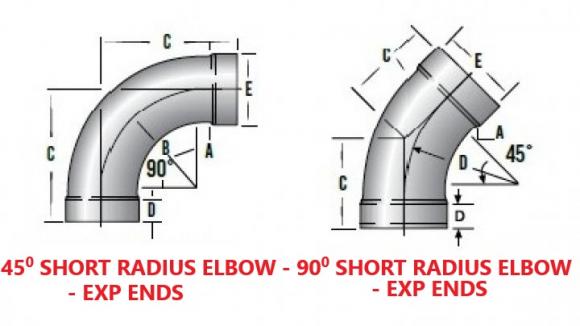

Short Radius Elbows

- 30° and 60° Elbows available

- 11 Gauge elbows are straight ends only

- Expanded ends through 6" only

- Expanded one side available

- Straight ends available on all sizes

Click THIS-LINK for details

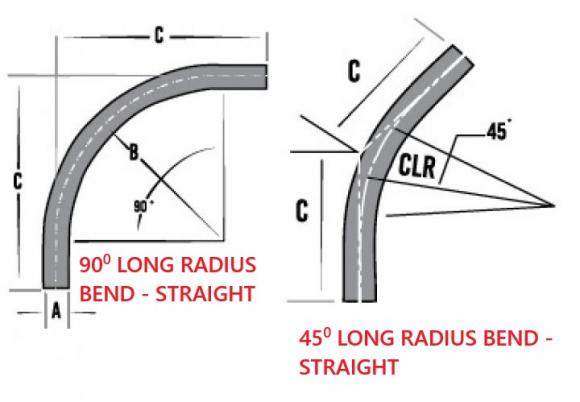

Standard Long Radius Elbows

Expanded ends are available upon request, except for 8 ", 10”, and all 11-gauge bends.

The nominal standard tangent is twice the tube outer diameter (OD), with a minimum of 6 inches. For a 10-inch bend, the nominal standard tangent is 22 inches. All standard bends have straight ends. Stainless parts are segmented.

Click THIS-LINK for details

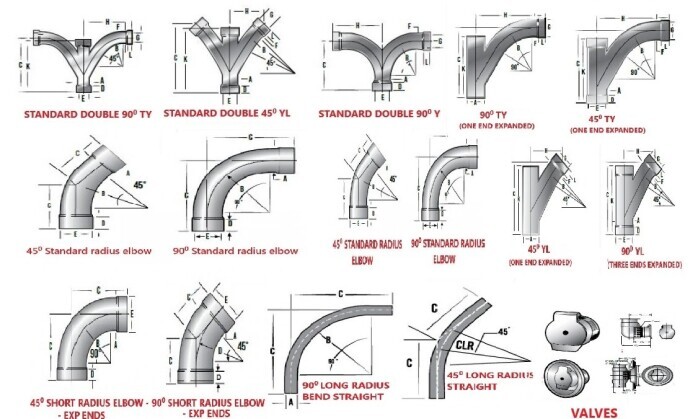

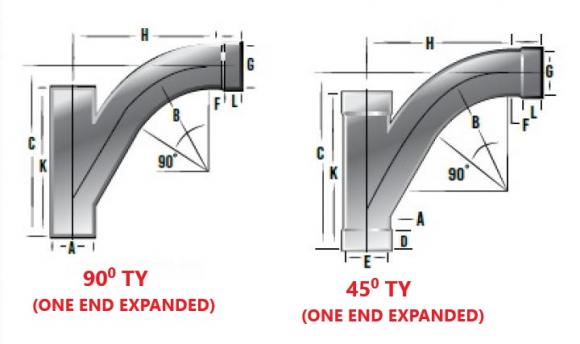

Standard 90° TYs

- 2-1/8” through 14” OD

- Wall Thickness: 16, 14, 12, (11 Gauge Available in Straight Ends Only)

- (16 Gauge: 2-1/8” to 4” OD) (14 Gauge: 5” to 8” OD) (12 Gauge: 10” to 14” OD)

- Materials: Carbon, Stainless, Aluminum, Galvanized Steel

- 11 Gauge TY’S available (Straight Ends Only)

- Expanded one side available

- Straight ends available on all sizes

Click THIS-LINK for details

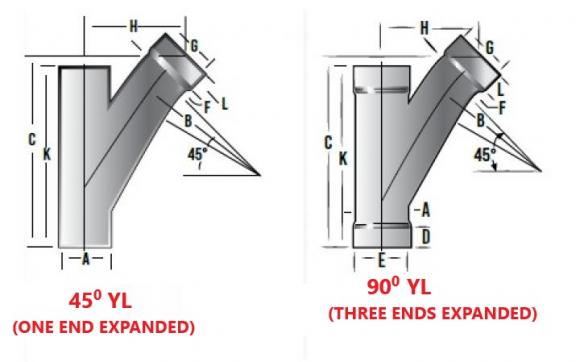

Standard 45° YLs

- 2-1/8” through 14” OD

- Wall Thickness: 16, 14, 12, (11 Gauge Available in Straight Ends Only)

- (16 Gauge: 2-1/8” to 4” OD) (14 Gauge: 5” to 8” OD) (12 Gauge: 10” to 14” OD)

- Materials: Carbon, Stainless, Aluminum, Galvanized Steel

- 11 Gauge YLs Straight ends only

- Straight and Exp combo ends

- Straight ends available

Click THIS-LINK for details

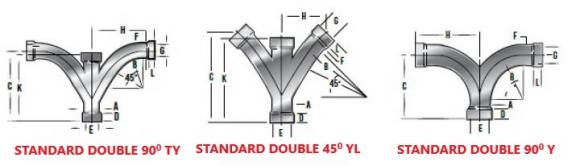

Standard Double 45 and 90 TYs

Click THIS-LINK for details

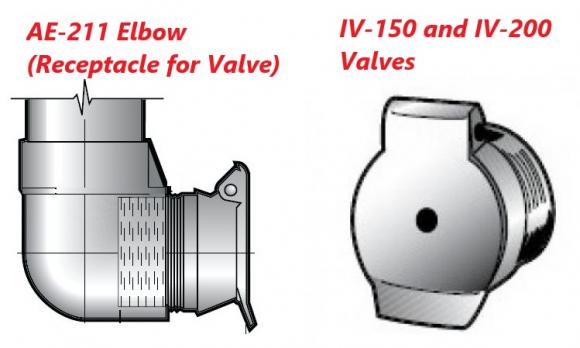

Inlet Valves for Hose Connection

Heavy Duty Inlet Valves for quick attachment of Hose to vacuum system.

- HA-200 is the Hose adapter.

- IV-200 is the 2" Valve.

- IV-200 screws into AE-211

These components are designed to be inserted into a 2” FNPT threaded fitting that adapts to a 2-1/8” tube size. The valves feature self-closing covers and are available in galvanized and stainless steel as well as nickel-plated models. Escutcheon plates enhance the aesthetic appeal of wall installations.

The same body is used for all three valves; only the bore varies. The IV-150 and IV-200 include a slight taper for hose adapter retention, while the IV-200-CLIP and IV-180 utilize a clip on the valve lid for retention. Hose adapters are made from heavy-duty galvanized steel.

Click THIS-LINK for details

Methods of Joining - Bolt Couplings or Heat Shrink

Click THIS-LINK for details

There are several methods of joining depending on the application and a variety of factors. The two most common are bolt-couplings and Shrink-Couplings. Bolt couplings require straight ends while shrink-sleeves require expanded ends.

There are various different types of bolt couplings, with different types of rubber gasketing, ground strap connectors, and other features. Send us an email: sales@controlledairdesign.com for more information.

Custom Laser Cutting

Send us your drawing and specifications of your design and we will send you a quote.

Installation Components and other fittings

See the links below for additional information, or call (800) 635-0298

Related Files

- Vacuum & Tubing Fitting Catalogue

- Vacuum Tubing

- Valves

- Standard Radius Elbows

- Long Radius Elbows

- Standard 90 TYs

- Standard 90 Tys - Continued

- Standard 45 YLs

- Standard 45 YLs - Continued

- Standard Double 90 TYs

- Standard Reducer Ciuplings

- Straight Female Adapter

- Standard Female adapters- Continued

- Male Adapter Nipples

- Accessories