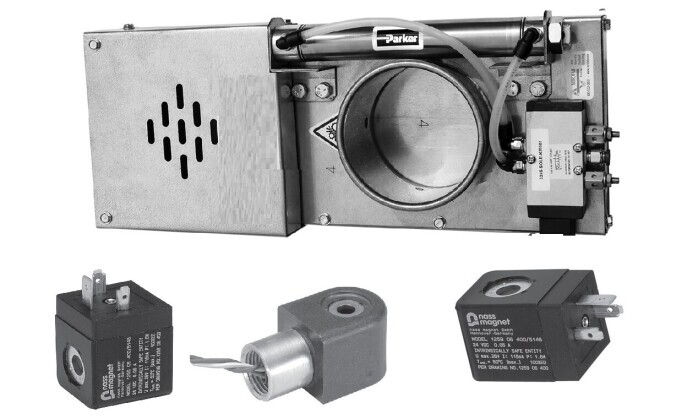

Blast Gates with Explosion Proof Solenoids

Blast gates serve as energy-saving devices for industrial dust extraction in situations where extraction isn't constantly required and manual control needs to be removed.

Explosion Proof Solenoids for Blastgates

Intrinsically safe solenoid valves (“E” option)

Hazardous location class:

- Class I; Groups A, B, C & D

- Class II; Groups E, F, & G

- Class III; Div. I

- For use in low voltage (24VDC) Intrinsically Safe applications.

- NO OTHER VOLTAGE IS APPROVED.

- Comes standard with non-lighted solenoid connector.

- Coil width: 30mm

- Must be connected to an FM approved Barrier.

- For dimensions, reference standard solenoid models.

- Maximum internally piloted valve pressure is 115 PSIG.

- Pressures to 145 PSIG can be used when external pilot is

- utilized and pilot pressure is limited to 115 PSIG.

- The intrinsically safe coil width (30mm) is wider than the body

- width of valve type A & B valves. If mounted on a manifold, the

- valves need to be staggered to fit and must be single solenoid valves only

Hazardous duty solenoid valves (“F” option)

Hazardous location class:

- Class I; Zone I EX, M, II & T4

- Class I; Div. I, Groups A, B, C, & D

- Class II & III; Div. I, Groups E, F, & G

- Comes standard with 1/2" conduit connection.

- Coil width: 36mm

- Voltage range = ±10%

- Ambient temperature range = -20°C (-4°F) to 60°C (140°F) Duty factor = 100%

- IP65 Rated (with connected conduit connector)