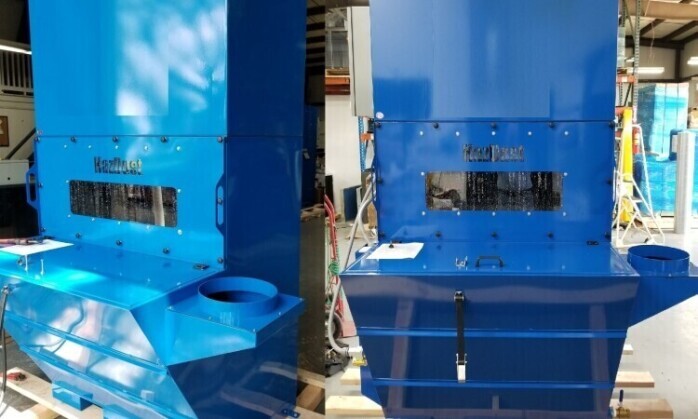

Aluminum and Titanium Dust Wet Collection

Ducted Wet Collector Systems for NFPA 660 (484) Compliance.

Ducted Filtration for Explosive Metal Powders

This OSHA/NFPA Compliant Electrical Package provides an automatic start from a closed contact at the process machinery. The machine will interrupt the circuit if the water level is too high or low. This machine contains an Ultrasonic water level sensor and valve, a hazardous gas exhaust vent, PLC, time delay, a warning light, an alarm and NEMA 12 enclosure. Every Wet Dust Collector is tested and run before leaving our shop to ensure correct CFM production and water doesn’t migrate up and out of the machine. When correct water level is maintained, our wet dust collectors don’t weep, seep or leak.

Click here to see a Case Study

Conductive Dust Removal from Robotic-Cell Applications

Once we learn the details of your application we will send a detailed quote with specifications. This usually starts with a teams chat and gathering of details. We come up with a proposal that we can quantify with math and referencing of safety regulations.

We have a full range of wet downdraft and ducted wet collectors for safe capture of aluminum dust and other conductive metal powders. Our Wet Collection ducted systems are designed to be used indoors in manufacturing and research locations to collect explosive metal dusts from various processes. We have a lot of experience with automation and robotic manufacturing systems as well as Aerospace, Defense, Research, and countless others. We will also be able to help you with OSHA and NFPA compliance by showing you how to deal with each specific explosive metal dust application. Call us today with the details of your unique application.

Click here to see a Case Study

Specifications for Ducted Wet Collectors:

| Unit Type | HP | CFM | Inlet |

|---|---|---|---|

| HAZDUST1800 | 5 | 1500 | 8 inches |

| HAZDUST3000 | 10 | 2400 | 10 inches |

| HAZDUST4800 | 15 | 4500 | 14 inches |