Click HERE to see the Spark Chamber with Water Bath

The Enclosure creates a Negative Pressure Zone for better capture

The SMOKE-CART features AUTO filter-cleaning and a dual-capture design that pulls air from the back as well as the tabletop.

That means the smoke has nowhere else to go but through the HEPA and is returned to the workplace as clean, breathable air.

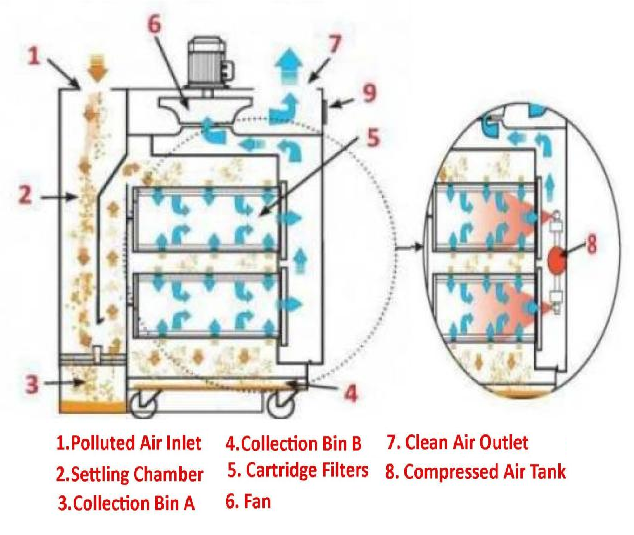

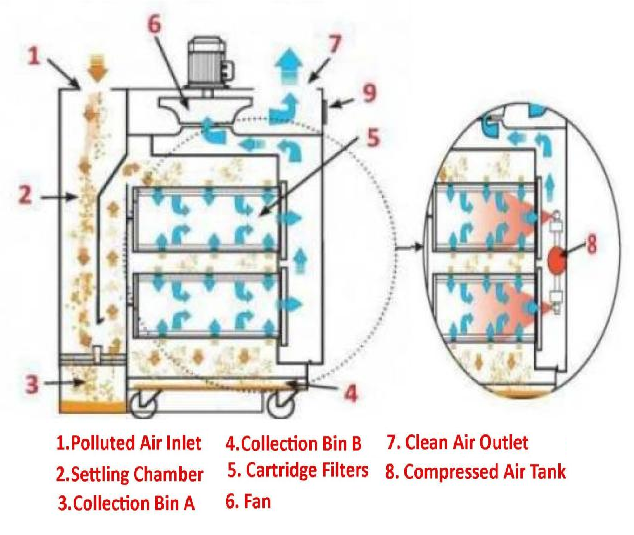

The air is pulled through the top, then through a pre-chamber equipped with a spark trap and a stainless steel collecting bin.

A programmable electronic compressed air cleaning system keeps the cartridges in perfect working order. The horizontal arrangement of cartridges allows for 'easy access and quick maintenance of the filter section. The filtered air is re-integrated where permitted into the work environment, leading to significant energy savings.

120V single-phase “plug and play” design. Fully automatic filter cleaning, and a stainless steel water bath for guaranteed neutralization of live glowing embers. The Smoke-Cart requires a ¼" airline for the AUTOMATIC Filter-Cleaning System.

Enhanced protection, same reliable performance. The POLIJET downdraft table features a frontal enclosure added on request to create a negative-pressure zone. The enclosure enhances operator safety and fume containment during grinding and welding while maintaining the same efficiency and performance that define every POLIJET system.

A downdraft with a custom enclosure creates a contained workspace, pulling dust, fumes, or smoke downwards through a perforated surface, ideal for hazardous tasks like sanding, grinding, or spray painting, offering superior air quality by surrounding the work area to block cross-drafts, with configurations varying from portable tables to large booths with specialized filtration for specific contaminants. These systems combine standard downdraft technology (perforated table, fan) with custom features like enclosures, specific filters (HEPA, carbon), and controls, ensuring effective source capture for applications from woodworking to industrial finishing