What does Hazardous Locations (HAZLOC) mean?

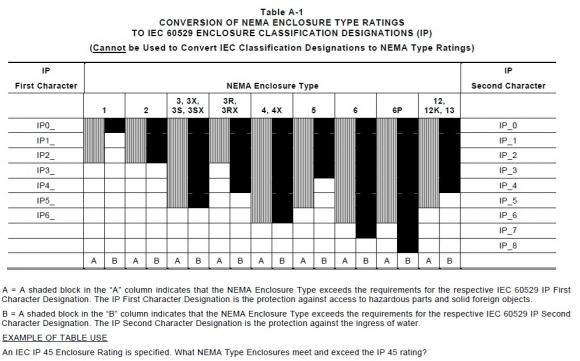

These ratings help ensure that the chosen enclosure is suitable for the specific application and environment.

NEMA ratings are a standard system developed by the National Electrical Manufacturers Association (NEMA) to classify electrical enclosures based on their ability to protect internal components and personnel from external environmental conditions and hazards.

NEMA ratings indicate the level of protection an enclosure provides against various environmental factors like dust, water, and corrosion.

The ratings help engineers and manufacturers select the appropriate enclosure for their specific needs, ensuring that the enclosure can withstand the intended operating conditions.

NEMA ratings also consider protection against personnel access to hazardous parts within the enclosure.

NEMA 1 (General Purpose):

Designed for indoor use and provides protection against light dust and indirect splashing, but it is not dust-tight.

NEMA 3R (Weatherproof):

Primarily for outdoor use, offering protection against rain, ice, and snow.

NEMA 4 (Watertight):

Designed for both indoor and outdoor use, offering protection against falling dirt, rain, sleet, snow, windblown dust, splashing water, and hose-directed water.

NEMA 4X (Corrosion-Resistant):

Similar to NEMA 4, but with additional corrosion resistance for use in harsh environments.

NEMA 12 (Industrial):

Suitable for indoor use and provides protection against falling dirt, circulating dust, and lint.

NEMA 4X (Corrosion-Resistant):

Similar to NEMA 4 but with added corrosion resistance for use in harsh environments.

Type 5 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and settling airborne dust, lint, fibers, and flyings); and to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing).

Type 6 Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (hose directed water and the entry of water during occasional temporary submersion at a limited depth); and that will be undamaged by the external formation of ice on the enclosure.

Type 6P Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (hose directed water and the entry of water during prolonged submersion at a limited depth); that provides an additional level of protection against corrosion and that will be undamaged by the external formation of ice on the enclosure.

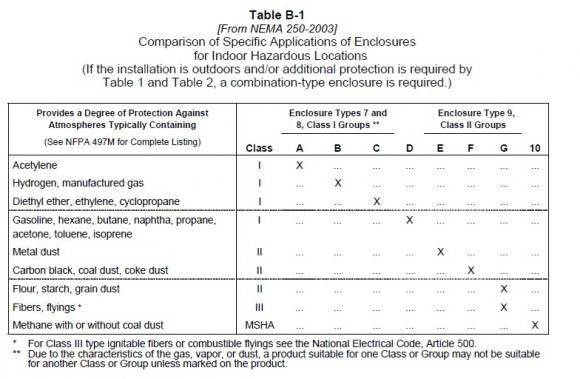

In Hazardous Locations, when completely and properly installed and maintained, Type 7 and 10 enclosures are designed to contain an internal explosion without causing an external hazard. Type 8 enclosures are designed to prevent combustion through the use of oil-immersed equipment. Type 9 enclosures are designed to prevent the ignition of combustible dust.

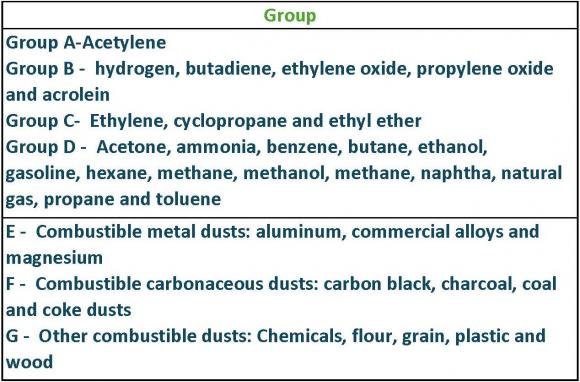

Type 7 Enclosures constructed for indoor use in hazardous (classified) locations classified as Class I, Division 1, Groups A, B, C, or D as defined in NFPA 70.

Type 8 Enclosures constructed for either indoor or outdoor use in hazardous (classified) locations classified as Class I, Division 1, Groups A, B, C, and D as defined in NFPA 70.

Type 9 Enclosures constructed for indoor use in hazardous (classified) locations classified as Class II, Division 1, Groups E, F, or G as defined in NFPA 70.

Type 10 Enclosures constructed to meet the requirements of the Mine Safety and Health Administration, 30 CFR, Part 18.

Type 12 Enclosures constructed (without knockouts) for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and circulating dust, lint, fibers, and flyings); and to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing).

Type 12K Enclosures constructed (with knockouts) for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and circulating dust, lint, fibers, and flyings); and to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing).

Type 13 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and circulating dust, lint, fibers, and flyings); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing); and to provide a degree of protection against the spraying, splashing, and seepage of oil and non-corrosive coolants

Sprecher+Schuh NEMA Type 4/4X/7/9 Explosion Proof Starters

VL5030 Baldor Explosion Proof General Purpose Motor, Specification Number 35E373-0199G1, UPC 781568451663

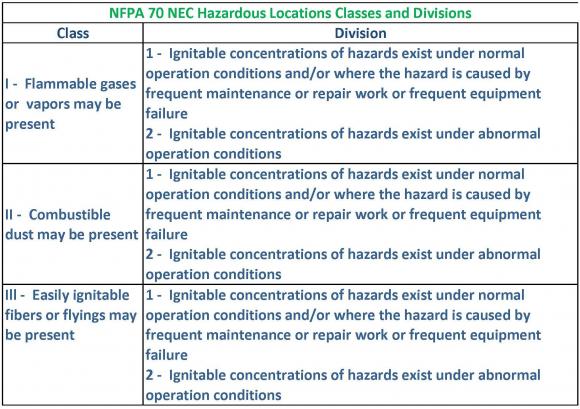

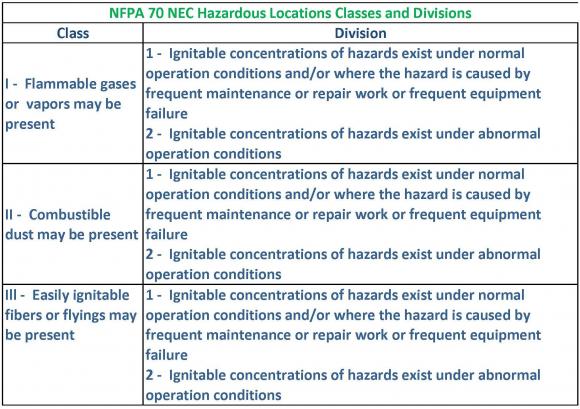

Class I: Gases or vapors. Class I hazardous areas may contain flammable vapors or gases in quantities large enough to cause a fire or an explosion. Examples of these gases and vapors include hydrogen, carbon monoxide, and ethylene oxide.

Class II: Dust. Class II hazardous areas may contain combustible or conductive dust in quantities large enough to cause a fire or an explosion. Examples of these dusts include metal dusts such as aluminum dust or carbon-based dusts such as coal dust.

Class III: Fibers. Class III hazardous areas may contain fibers and small airborne parts in quantities large enough to ignite and cause a fire or an explosion. Examples of these include wood, plastic, and grain.

Div. I High-Probability locations are defined as an area where the amount of combustible dust is either suspended in the air or accumulated on surfaces in a sufficient concentration to allow for ignition.

All day production would usually be Div. 1.

Div. II Low Probability locations are usually defined as maintenance areas, or intermittent production.