Key aspects of welding and thermal cutting filtration

To mitigate these risks, filtration systems are used to capture and remove these contaminants from the air.

Why is filtration important?

Worker Health:

Welding and thermal cutting processes release various metal fumes and gases, some of which are toxic and can cause respiratory problems, skin irritation, and long-term health issues

Environmental Compliance:

Regulations often require businesses to control emissions of dust and fumes to protect the environment.

Equipment Protection:

Uncontrolled fumes can accumulate on machinery, electrical components, and other equipment, leading to damage and downtime.

Productivity:

A healthy and safe working environment can boost productivity by reducing worker stress and absenteeism.

How do filtration systems work?

Extraction:

Welding fume extractors use fans or suction to draw in the air containing fumes and dust.

Filtration:

The captured air then passes through a filter, which removes the contaminants.

Recycling or Exhaust:

The clean air is either recycled back into the workplace or expelled outside, depending on the specific filtration system.

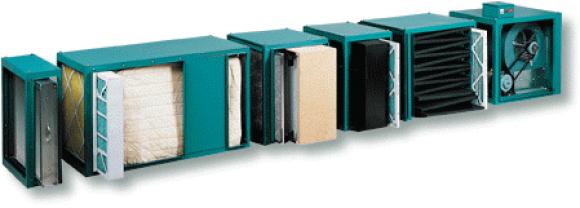

Types of Filtration Systems:

Dust and Fume Collection Systems:

These systems are designed to capture and filter welding fumes and dust from processing areas or entire facilities.

HEPA Filters:

These filters are highly efficient in capturing fine particles, including those found in welding fumes.

Active Carbon Filters:

These filters are used to remove paint mists and other gaseous contaminants from welding fumes.

A custom blend of activated carbon pellets and potassium permanganate pellets is used to eliminate odors. Having the right amount of “dwell time” for the VOC within the carbon is essential to the success of the unit.

Different contaminants call for different kinds of filtration

Different contaminants call for different kinds of filtration. HEPA won't eliminate VOC and Carbon won't filter particulate all that well.

Sometimes a combination of filtration is called for. What order they go in is crucial also.

Click on some of the links below or give us a call!

Related Files

Related Products

- Backdraft Collector for VOC

- Metal Grinding Downdraft Table

- Exhaust HEPA and Carbon Plenums

- Explosion-Proof Vacuums | 3rd Party Certified

- Fume Extraction Arms

- Gun Range Vacuums

- HD High-Performance HEPA Downdraft Tables

- HEPA Filters for Dust Collection | Industrial

- Intrinsically Safe Pneumatic Vacuums XP

- Industrial Vacuums for the Metal-Working Industry

- Dust Collector with Explosion-Vent

- Pharma Dust Collector

- Iperjet DF Cartridge Dust Collectors