What does Hazardous Locations (HAZLOC) mean?

The spark trap system captures sparks generated during welding, sanding, or polishing operations on metal parts

Large-scale fume extraction systems for multi-station industrial applications.

Double-ply silver construction silicone coated fiberglass fabric hose with a silver heat-resistant fiberglass liner mechanically crimped in a continuous process.

Blast gates serve as energy-saving devices for industrial dust extraction in situations where extraction isn't constantly required and manual control needs to be removed.

High Bulk-Density material like wet sand can be tricky to discharge because they weigh so much.

Industrial Vacuum Tools - General Purpose

Lightweight Overhead Carbon Fiber Cleaning Kit for Explosive atmospheres

The AER POD is a practical solution in production spaces where airborne dust and odor is a problem

The highly porous structure of activated carbon binds odor molecules and pollutants.

To mitigate these risks, filtration systems are used to capture and remove these contaminants from the air.

Welding and thermal cutting processes release various metal fumes and gases, some of which are toxic and can cause respiratory problems, skin irritation, and long-term health issues

Regulations often require businesses to control emissions of dust and fumes to protect the environment.

Uncontrolled fumes can accumulate on machinery, electrical components, and other equipment, leading to damage and downtime.

A healthy and safe working environment can boost productivity by reducing worker stress and absenteeism.

Welding fume extractors use fans or suction to draw in the air containing fumes and dust.

The captured air then passes through a filter, which removes the contaminants.

The clean air is either recycled back into the workplace or expelled outside, depending on the specific filtration system.

These systems are designed to capture and filter welding fumes and dust from processing areas or entire facilities.

These filters are highly efficient in capturing fine particles, including those found in welding fumes.

These filters are used to remove paint mists and other gaseous contaminants from welding fumes.

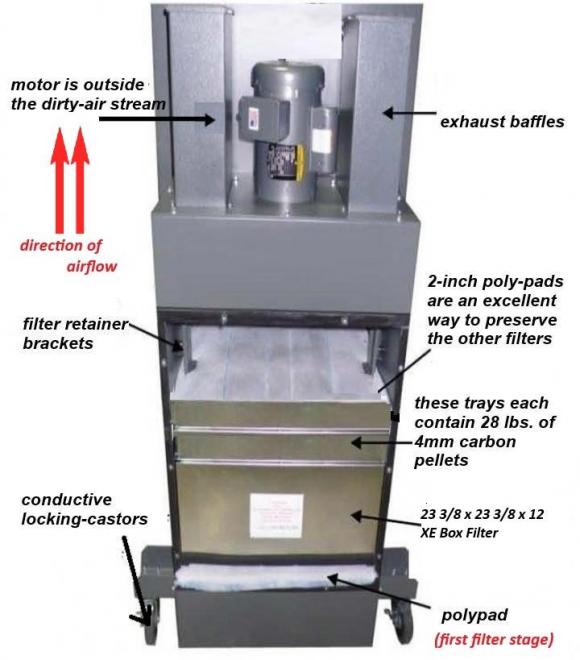

A custom blend of activated carbon pellets and potassium permanganate pellets is used to eliminate odors. Having the right amount of “dwell time” for the VOC within the carbon is essential to the success of the unit.

Different contaminants call for different kinds of filtration. HEPA won't eliminate VOC and Carbon won't filter particulate all that well.

Sometimes a combination of filtration is called for. What order they go in is crucial also.

Click on some of the links below or give us a call!

The Barrel Vac is able to convert a 55 gallon drum into a large capacity vacuum.

Div 2 explosion-proof vacuum cleaners are designed for specific applications involving the pickup of hazardous materials

Compact, powerful floor scrubbers that will take care of all of your industrial and commercial floor cleaning needs.

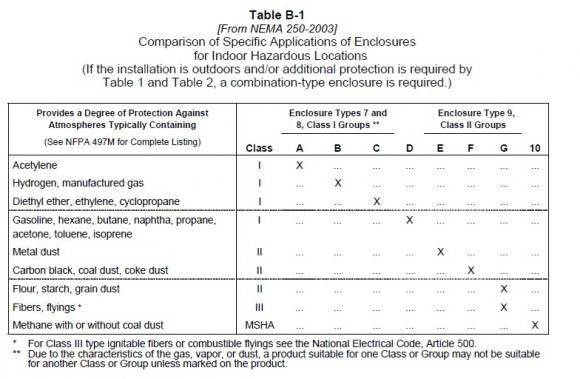

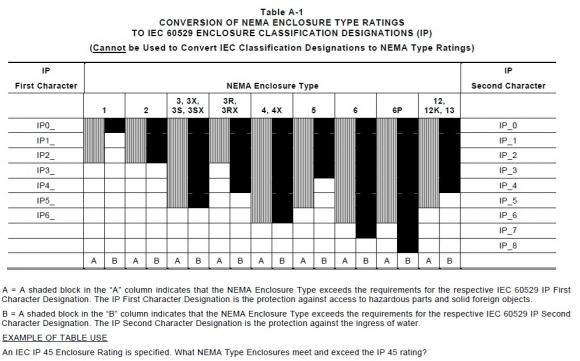

These ratings help ensure that the chosen enclosure is suitable for the specific application and environment.

NEMA ratings are a standard system developed by the National Electrical Manufacturers Association (NEMA) to classify electrical enclosures based on their ability to protect internal components and personnel from external environmental conditions and hazards.

NEMA ratings indicate the level of protection an enclosure provides against various environmental factors like dust, water, and corrosion.

The ratings help engineers and manufacturers select the appropriate enclosure for their specific needs, ensuring that the enclosure can withstand the intended operating conditions.

NEMA ratings also consider protection against personnel access to hazardous parts within the enclosure.

NEMA 1 (General Purpose):

Designed for indoor use and provides protection against light dust and indirect splashing, but it is not dust-tight.

NEMA 3R (Weatherproof):

Primarily for outdoor use, offering protection against rain, ice, and snow.

NEMA 4 (Watertight):

Designed for both indoor and outdoor use, offering protection against falling dirt, rain, sleet, snow, windblown dust, splashing water, and hose-directed water.

NEMA 4X (Corrosion-Resistant):

Similar to NEMA 4, but with additional corrosion resistance for use in harsh environments.

NEMA 12 (Industrial):

Suitable for indoor use and provides protection against falling dirt, circulating dust, and lint.

NEMA 4X (Corrosion-Resistant):

Similar to NEMA 4 but with added corrosion resistance for use in harsh environments.

Type 5 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and settling airborne dust, lint, fibers, and flyings); and to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing).

Type 6 Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (hose directed water and the entry of water during occasional temporary submersion at a limited depth); and that will be undamaged by the external formation of ice on the enclosure.

Type 6P Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (hose directed water and the entry of water during prolonged submersion at a limited depth); that provides an additional level of protection against corrosion and that will be undamaged by the external formation of ice on the enclosure.

In Hazardous Locations, when completely and properly installed and maintained, Type 7 and 10 enclosures are designed to contain an internal explosion without causing an external hazard. Type 8 enclosures are designed to prevent combustion through the use of oil-immersed equipment. Type 9 enclosures are designed to prevent the ignition of combustible dust.

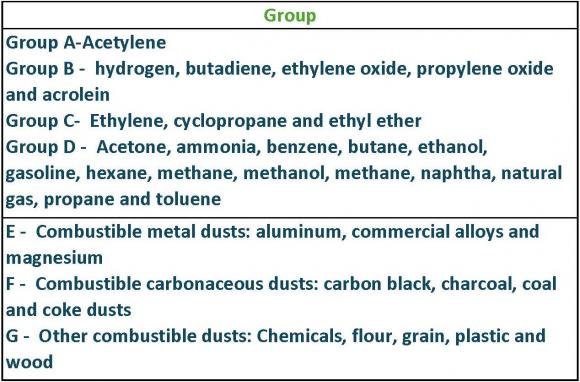

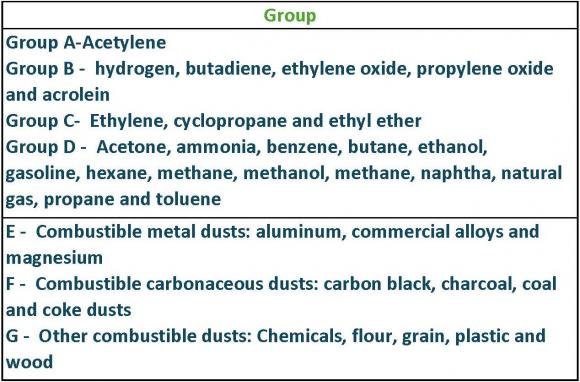

Type 7 Enclosures constructed for indoor use in hazardous (classified) locations classified as Class I, Division 1, Groups A, B, C, or D as defined in NFPA 70.

Type 8 Enclosures constructed for either indoor or outdoor use in hazardous (classified) locations classified as Class I, Division 1, Groups A, B, C, and D as defined in NFPA 70.

Type 9 Enclosures constructed for indoor use in hazardous (classified) locations classified as Class II, Division 1, Groups E, F, or G as defined in NFPA 70.

Type 10 Enclosures constructed to meet the requirements of the Mine Safety and Health Administration, 30 CFR, Part 18.

Type 12 Enclosures constructed (without knockouts) for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and circulating dust, lint, fibers, and flyings); and to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing).

Type 12K Enclosures constructed (with knockouts) for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and circulating dust, lint, fibers, and flyings); and to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing).

Type 13 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and circulating dust, lint, fibers, and flyings); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing); and to provide a degree of protection against the spraying, splashing, and seepage of oil and non-corrosive coolants

Sprecher+Schuh NEMA Type 4/4X/7/9 Explosion Proof Starters

VL5030 Baldor Explosion Proof General Purpose Motor, Specification Number 35E373-0199G1, UPC 781568451663

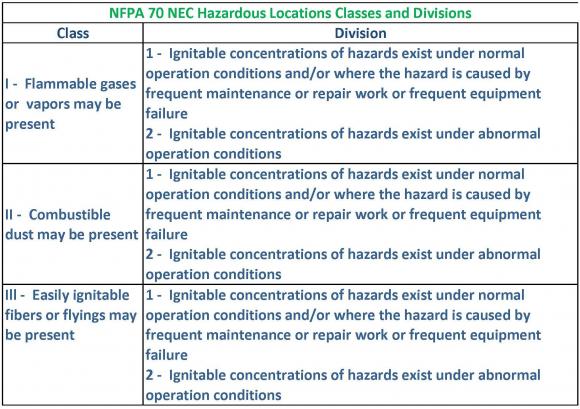

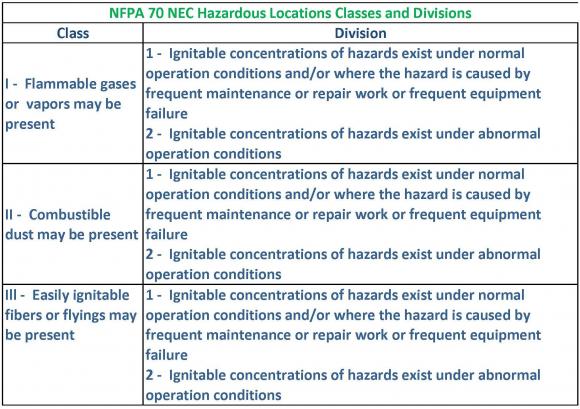

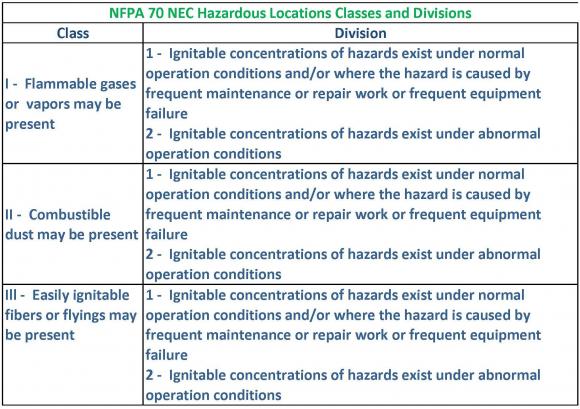

Class I: Gases or vapors. Class I hazardous areas may contain flammable vapors or gases in quantities large enough to cause a fire or an explosion. Examples of these gases and vapors include hydrogen, carbon monoxide, and ethylene oxide.

Class II: Dust. Class II hazardous areas may contain combustible or conductive dust in quantities large enough to cause a fire or an explosion. Examples of these dusts include metal dusts such as aluminum dust or carbon-based dusts such as coal dust.

Class III: Fibers. Class III hazardous areas may contain fibers and small airborne parts in quantities large enough to ignite and cause a fire or an explosion. Examples of these include wood, plastic, and grain.

Div. I High-Probability locations are defined as an area where the amount of combustible dust is either suspended in the air or accumulated on surfaces in a sufficient concentration to allow for ignition.

All day production would usually be Div. 1.

Div. II Low Probability locations are usually defined as maintenance areas, or intermittent production.

Proactively acquiring the right equipment and implementing proper protocols will mitigate various issues in the future.

Dust particles can irritate the nose, throat, and lungs, causing symptoms such as coughing, sneezing, and difficulty breathing.

Some individuals may develop allergic reactions to specific dust components, resulting in symptoms like skin rashes, nasal congestion, and breathing difficulties.

For those with asthma, dust exposure can exacerbate symptoms, leading to increased wheezing, chest tightness, and difficulty breathing.

Prolonged exposure to dust, especially certain types like silica dust, may lead to chronic lung diseases such as silicosis, which can impair lung function and increase the risk of tuberculosis and lung cancer.

Cement dust contains silica, stainless steel dust contains hexavalent chromium. Both are known carcinogens. Having a layer of dust on a floor is a hazard every time that dust is kicked by human traffic, equipment, HVAC, and a variety of means.

We have solutions for every type and size of industrial or commercial floors. From critical environments where HEPA is needed, banquet halls to tennis courts, dusty wood shops, we have a solution. Fill out the form and we will be in touch.

This page is to demonstrate cost saving measures of owning versus renting for big cleanups.

In 2017, OSHA updated its silica dust regulations, reducing the permissible exposure limit (PEL) to 50 micrograms per cubic meter of air (µg/m3) averaged over an 8-hour workday. This standard also established an action level (AL) of 25 µg/m3. The updated rules, first enforced in September 2017 for the construction industry, require employers to ensure that worker exposure to silica dust remains below the PEL.

The PEL is now set at 50 µg/m3, meaning the maximum amount of silica dust an employee can be exposed to over an 8-hour period is 50 micrograms per cubic meter of air.

OSHA requires employers to use engineering controls, work practice controls, and respirators to keep worker exposure to silica dust at or below the PEL. One of these methods of controlling the dust is use of HEPA Filtration.

The return on investment is instantly apparent when you contrast the costs of renting a vacuum truck versus owning a vacuum that you can slide into your own truck and take care of remote spills instantly.

For mines or steel mills where big vacuuming jobs can only be done with rental vac trucks, owning an ATLAS Portable HEPA Vacuum ends up paying for itself in no time. Fill in the web form and we will be in touch to discuss your application so that we can send you a quote.

At no additional cost, we offer decades of knowledge and experience, available at your disposal every day of the week.

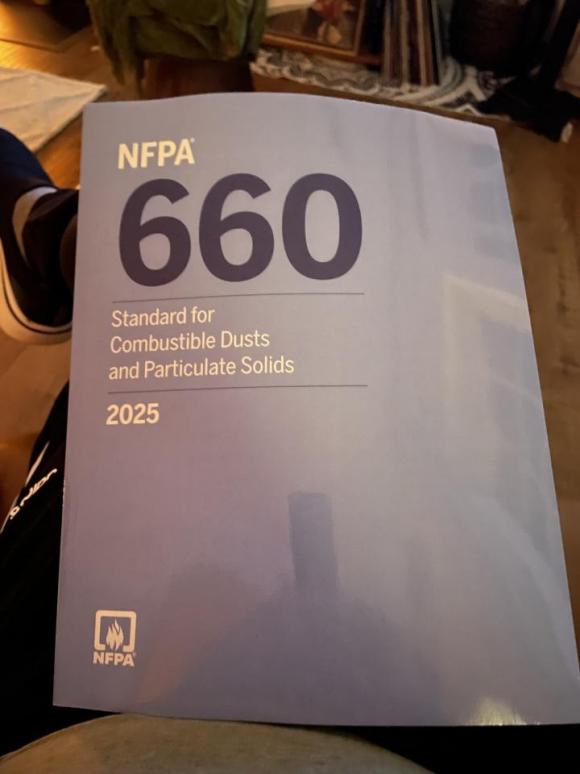

We use NFPA 660 as a guide to recommend the appropriate solution in terms of compliance and productivity. We believe that you shouldn't take any short cuts with critical equipment purchases as too many things are at stake.

If you see a “buy-it-now” next to an XP vacuum or dust collector that is not a good sign. There are too many things that can go wrong doing that.

You can buy the correct vacuum or dust collector frum us and we will sign off on it, and provide full support going forward.

We have every kind of industrial vacuum and dust collector for ORDLOC and HAZLOC. Call us today, and don't take chances with aggressive vacuum providers with buy-it-now ads that pop up everywhere after you visit their website. We believe that purchasing an XP vac requires a detailed discussion about the application. We are always available to answer the phone before, during, and after you purchase the equipment.

More about us HERE

This is a common claim from vacuum companies that lack a dust collector to offer you for your pouring or batching process.

The reason a vacuum won't function properly as a “dust collector”.

A vacuum won't function properly as a “dust collector” because the area has a direct relationship to air volume. Vacuums feature a small diameter inlet to achieve the required capture velocity when pulling dirt and dust off a flat surface. Expanding the inlet to allow for greater volumetric flow directly reduces static lift, diminishing vacuuming power.

A wider inlet and a different fan design are necessary to effectively capture airborne dust. Dust collectors lack the high static lift that vacuums possess, as they would only end up sucking up the product when all you need them to do is capture the "lighter-than-air" nuisance dust.

When you purchase equipment from us, you are also getting a relationship at no additional cost that will come in very handy whenever you have dust, mist, oil, or VOC in your facility that needs to be addressed while keeping compliance, safety, and productivity at the forefront. Free professional help for our clients is always just a call or email away. We are prompt, highly technical, and will treat your unique application with the utmost care, respect, and dedication.

For Conductive Metal Dust a Wet Collector is really your only choice

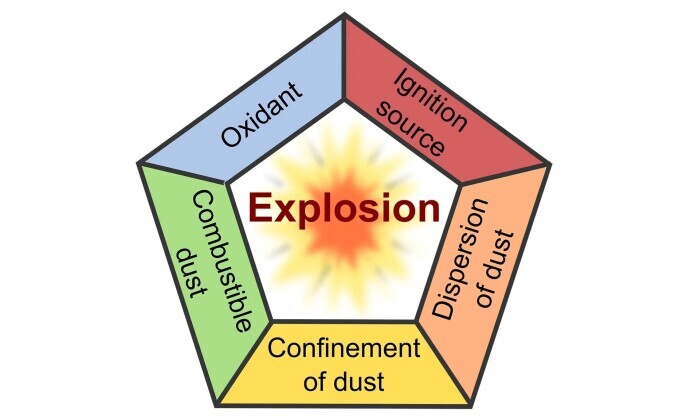

A Dust Hazard Analysis (DHA) is a systematic process defined by NFPA 660 to identify and evaluate potential fire, deflagration, and explosion hazards associated with combustible dust and particulate solids in a facility, offering recommendations to manage those risks.

Once your dust is analyzed it is best to follow the direction of your AHJ or EHS, and the recommendations given by the testing lab.

If you are sanding conductive metal, a Wet Dust Collector is essential. OSHA prohibits the use of HEPA filters in Wet Collectors unless they are equipped with a heat sensor that shuts them down. This is because aluminum fines can remain in the HEPA filter after drying, which poses a fire hazard and has led to fires.

Other than conductive dusts, Wet Collection is quite inefficient and can lead to a lot of dust-bypass. Having visited lots of plants where wet dust collection is used, the first thing you will notice is dust all over the floor. This is because most wet dust collectors don't have proper HEPA filtration as water and paper are not a good combo, for a lot of reasons.

If you are sanding plastics, or graphite, anything with Silica, then you need proper HEPA Filtration that captures particulate down to .3 micron at 99.97% efficient. Water as your main filter will only allow the dust to completely bypass the unit.

Traditionally, non-industrial ventilation systems (HVAC) were designed to regulate temperature, humidity, and odors.

Sick Building Syndrome (SBS) refers to a situation where building occupants experience a variety of health and comfort issues that seem linked to the time spent in a particular building, but where no specific illness or cause can be identified

Any ventilation deficiency must be verified by measurement.

The complete Manual can be accessed in the link below:

Toxic dust and volatile organic compounds, such as formaldehyde, often contribute to indoor air contamination. The products available in these links are designed to integrate with your process, ensuring that the air remains clean and breathable without sacrificing productivity.

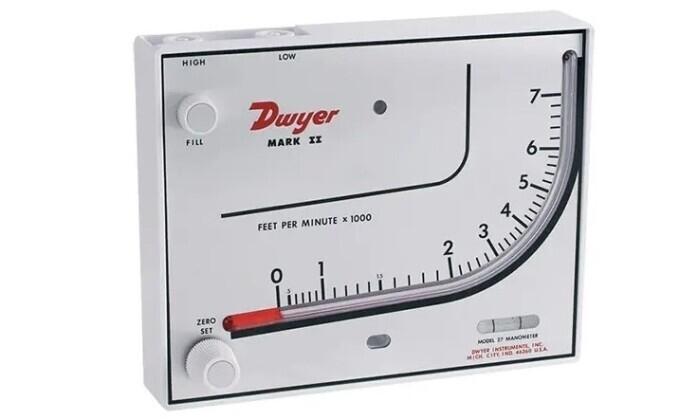

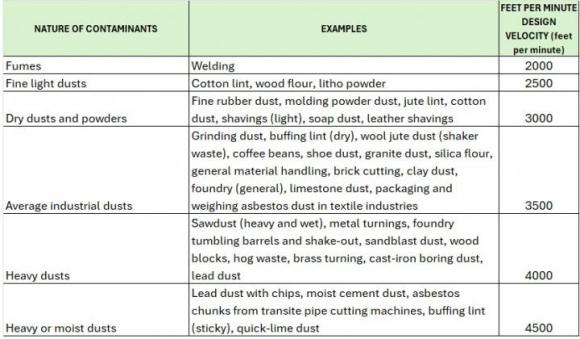

Minimum Conveying Velocities of common contaminants to prevent dust "laying down" in ducting

If the right amount of CFM isn't provided, then over time the duct will fill up with dust accumulation and eventually collapse. We take several factors into consideration to calculate how many CFM are required. Elbows and other resistance points are all taken into consideration to ensure effective and timely evacuation of the contaminants. .

An ideal scenario for optimal operation is a capture velocity of 150 to 300 fpm.

CFM = (Room Volume × ACH) / 60

Step 1: Measure the room

First, you need to find the room's total volume in cubic feet.

Step 2: Calculate the room's volume

Multiply the room's dimensions to find its volume.

Step 3: Determine the required ACH

Air changes per hour (ACH) indicates how many times the air in a room is replaced each hour. Recommended ACH values vary by room type: Bedrooms (5–6), Living Rooms (6–8), Kitchens (7–8), Bathrooms (7–8), and Laundry Rooms (8–9).

Step 4: Calculate the CFM

Use the room's volume and the chosen ACH in the CFM formula.

Example calculation

For a 12 ft by 14 ft living room with a 10 ft ceiling and a target ACH of 6:

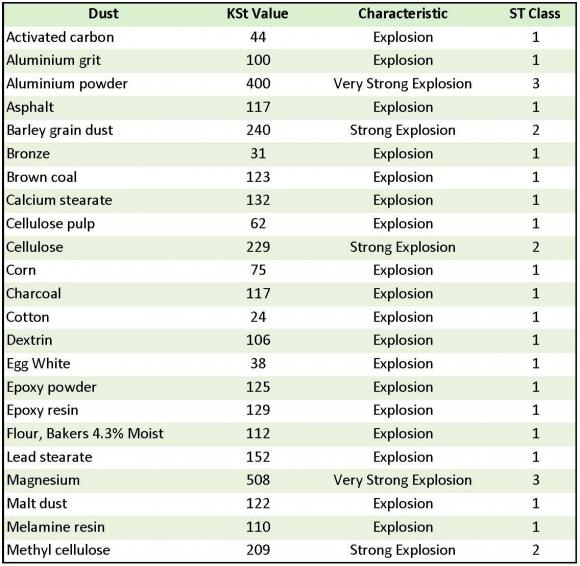

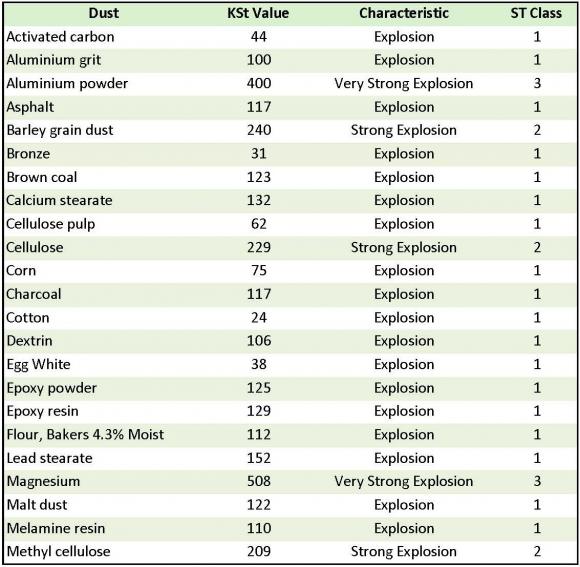

This classification system is designed to help guide you to the correct equipment choice.

Kst values, measured in bar.m/s, quantify the relative explosion severity of dusts, with higher values indicating a more explosive potential. Here's a breakdown of common dusts and their Kst values, along with their corresponding explosion classes:

Solutions for welding and machine shops have that clouds of haze and smoke

Consider source capture systems, tip extraction, and enclosures to minimize exposure and ensure compliance with safety standards.

Hexavalent chromium (Cr(VI)), a toxic form of chromium, is a known human carcinogen, particularly when inhaled, leading to increased risk of lung cancer and other cancers.

The Occupational Safety and Health Administration (OSHA) recognizes hexavalent chromium as a carcinogen and has specific regulations to limit worker exposure.

During welding, the high temperatures oxidize chromium in the metal to its hexavalent state (Cr(VI)), which is a toxic form of chromium.

Besides hexavalent chromium, welding fumes can contain other harmful substances like iron oxide, manganese, nickel, and other metal oxides.

The preferred method for capturing hex chrome dust is a Dust Collector or a Vacuum, with a High-Efficiency Particulate Air (HEPA) filter, which captures 99.97% of particles 0.3 microns in size.

Click HERE for more information.

Consider wet collectors for safely collecting conductive metals, explosive, or impact-sensitive materials.

Click HERE for more information.

This is a completely sealed vacuuming operation where there is no ambient exposure of the dust once it enters the hose. The Industrial vacuums utilizes HEPA Filtration and a direct-bagging system where the toxic dust goes directly into a bag with zero exposure to the operator.

Click HERE for more information.

Torch Extractors that couple a narrow suction hose to the welding gun is an excellent way of source extraction that stops and starts each time you lull the torch trigger.

Click HERE for more information.

Use high-efficiency nanofiber media with a tested MERV 15 or MERV 16 efficiency for primary dust collection filters.

Click HERE for more information.

Consider ambient dust collection systems or fume extractors to mitigate fumes throughout the facility.

Click HERE for more information.

Prevent the spreading of dust and fumes by vacuuming regularly with a HEPA vacuum.

Click HERE for more information.

A good option for welding smoke is overhead ambient style units. One or two of these in a shop can can the air clean all day. Email us the dimensions of your shop so that we can calculate how many CFM you will need.

Click HERE for more information.

Grain dust is highly combustible and can create an explosion in the right conditions .

Grain dust is highly combustible and can create explosive conditions. Explosion-proof vacuums are designed to safely collect and contain this dust, preventing ignition and potential disasters. Explosion-proof vacuums are designed to safely collect and contain this dust, preventing ignition and potential disasters.

For air-material separators handling combustible dust, a risk analysis should be provided to meet the goals of NFPA 660

9.8.2.1 * Where an explosion hazard exists within any operating greater than 8 ft3 (0.2 m 3 ) of containing volume, the equipment shall be protected from the effects of an explosion.

Vacuums and Dust Collectors for NFPA compliance and for ease of use and productivity.

Organic dust explosions are not new. Following 'The Great Mill Disaster' of 1878, a catastrophic grain mill explosion at The Washburn Mill in Minneapolis, Minnesota, significant measures were taken to prevent similar incidents.

Over the past 35 years, there have been more than 500 accidents, 675 injuries, and 180 deaths, all caused by one thing: flour dust, which is more explosive than gunpowder and 35 times more combustible than coal dust.

The explosion that destroyed Washburn A Mill, the world’s largest grain mill, along with several nearby mills, cut the city’s milling capacity by nearly half and claimed the lives of eighteen people. This incident, attributed to a buildup of grain dust, sparked extensive discussions and initiatives aimed at improving industrial safety and preventing the accumulation of combustible dust.

NFPA published it's first standard on combustible dust in 1923. So this isn't a new problem. Companies have been reluctant to do anything due to perceived high costs. In almost every case it is a cost saving measure to address the hazard. We are happy to help you with the first steps.

A wet dust collector, also known as a wet scrubber, uses water or another liquid to trap and remove dust particles from air streams, often preferred for applications involving potentially explosive or flammable materials.

Water is used to neutralize aluminum dust, where as neutralizing oil is used for titanium dust as water can be an accelerant in titanium fires.

Currently, there are no OSHA mandates on Combustible Dusts; there are Standards that need to be followed. Even though NFPA 660 isn't a law, you can still be held accountable for safety violations.

A Dust Hazard Analysis (DHA), as outlined by NFPA 660, is a systematic process for identifying and evaluating fire, flash fire, and explosion hazards associated with combustible dust and particulate solids in a facility, ultimately providing recommendations to manage these risks.

Click HERE for more information

An Explosion-Proof Vacuum System is a vacuum system capable of preventing the ignition of a specified gas or vapor and operates at such an external temperature that a surrounding flammable atmosphere will not be ignited. A Nationally Recognized Testing Lab (NRTL) must certify that a vacuum system is explosion-proof.

An Intrinsically Safe Vacuum is one that operates with no moving parts and no electrical parts. The power is supplied by compressed air that is fed into a tapered restriction also called a “venturi”. Intrinsically safe vacuums are made from non-sparking metals like stainless steel and aluminum. Mild steel is not suitable as it can create a spark when a nut or a screw is vacuumed. It will create a spark when it hits the wall of the vacuum dirt-bin.

NFPA 660 Chapter 8 Combustible Metals. Portable Vacuum Cleaners. The use of portable vacuum cleaners shall comply with 22.8.4.2.2. (B)*Due to the inherent hazards associated with portable electric vacuum cleaning systems, the equipment used for cleaning shall be identified for use in Class II, Group E atmosphere.

We take several factors into consideration. From the bulk density of the product being vacuumed, the Kst and Pmax values, to the electrical requirements under NEC 70. Safety as well as productivity are taken equally into consideration.

If your area is HAZLOC, then yes. If you area is ORDLOC and the Kst value of the powder is low, then an NFPA 660 Compliant Vacuum is required.

Vacuums made from non-sparking materials, motors located in the clean air stream, and critical filtration are built this way to ensure a safe and productive workplace.

Vacuum Hoses for use with Explosion-Proof Vacuums

Static electricity is a buildup of electric charges on objects. Charges build up when negative electrons are transferred from one object to another. The object that gives up electrons becomes positively charged, and the object that accepts the electrons becomes negatively charged. This can happen in several ways.

Conductivity is a material's ability to allow electrical charges (electrons) to move through it.

"Static dissipative" refers to materials or objects that allow static electricity to flow slowly and in a controlled manner, preventing sudden, potentially damaging electrostatic discharges (ESD).

A vacuum hose whose only means of eliminating static is a copper ground wire running through the helix is considered static dissipating. Lower concentrations of conductive resin are also regarded as static dissipating.

A Conductive Hose has higher levels of conductive resin impregnated within the hose construction.

The conductive hose is better for fighting static than the hose with a ground wire, contrary to what many people believe. A hose's static conductivity is measured in units of "sheet resistance" or ohms squared. You should look at the surface resistivity levels, not whether it has a ground wire.

AATCC Test Method 76-2001, "Electrical Surface Resistivity of Fabrics," determines the electrical resistance of fabrics, which can influence electrostatic charge accumulation.

AATCC is the American Association of Textile Chemists and Colorists

FDA Approved Static-Dissipative Hose impregnated with conductive resin to have a Surface Resistivity level: 108-1010 Ohms/Square

Conductive Hose impregnated with higher concentrations of conductive resin to have a Surface Resistivity Level: 103 - 105 Ohms/Square

Surface Resistivity Level:108 - 1010 Ohms/Square

Areas are divided into Class 1 Class 2, and Class 3. There are two divisions within each area.

Class I: Gases or vapors. Class I hazardous areas may contain flammable vapors or gases in quantities large enough to cause a fire or an explosion. Examples of these gases and vapors include hydrogen, carbon monoxide, and ethylene oxide.

Class II: Dust. Class II hazardous areas may contain combustible or conductive dust in quantities large enough to cause a fire or an explosion. Examples of these dusts include metal dusts such as aluminum dust or carbon-based dusts such as coal dust.

Class III: Fibers. Class III hazardous areas may contain fibers and small airborne parts in quantities large enough to ignite and cause a fire or an explosion. Examples of these include wood, plastic, and grain.

Div. I High-Probability locations are defined as an area where the amount of combustible dust is either suspended in the air or accumulated on surfaces in a sufficient concentration to allow for ignition.

All day production would usually be Div. 1.

Div. II Low Probability locations are usually defined as maintenance areas, or intermittent production.

Determining the right vacuum for your needs and compliance is a phone call away.

The right tool for the job is crucial. Having a lengthy background in working with installations and repairs, I can speak with the Plant Manager or Maintenance Tech and speak their language.

When a purchaser calls, I always insist on speaking with these people to get to the bottom of the actual needs in terms of application and compliance with all regs.

The NFPA compliance, the bulk density of the material you are vacuuming, and other factors are all considered.

“Our company has done a DHA, and the dust has a Kst 300. Our area is a designated Hazardous Location. (HAZLOC). What are our options?”

You have only one option here, and that is to use an appropriately certified vacuum or dust collector for the area.

“Our company has done a DHA, and the dust has a Kst of 98. Our area is an Ordinary Location. (ORDLOC).”

If the area is HAZLOC, then by all means, you can only use the appropriate vacuum with the correct markings and 3rd Party Certification. But if the area is ORDLOC and the dust is low Kst, then overspending on the wrong vacuum works against your needs. The fully XP vacuum can sometimes be less ergonomic and end up sitting in a closet. Purchasing a vacuum to check a box is the most common cause for this.

You can often tell if an area is ORDLOC if you can bring in a cell phone or if ordinary light switches are present. The misconception is that getting a fully explosion-proof vacuum for low Kst dust in ORDLOC is a good return on your money. Very often, it is the worst thing you can do. A fully explosion-proof vacuum is for an NFPA HAZLOC area with airborne flammable vapors. But if you are vacuuming wood dust in a warehouse or a production area, this certification doesn't provide anything in return. In this scenario, purchasing full XP is a mere CYA exercise. A 120V NFPA 660 Safe Vacuum can give around 300 cfm from a 120V circuit, and it checks your safety and compliance boxes. The full explosion-proof 120V model costs double and only has ⅓ of the vacuuming power.

We are always available to chat. We do several teams chats everyday and we go over the small details to ensure that you are getting the correct solution. Please feel free to reach out anytime!

Immersion systems are designed to neutralize the metal dust by submerging it in a liquid bath.

3.3.15.1* Combustible Metal Dust. A combustible metal dust particulate solid, including combustible fibers/flyings, that presents a fire, flash fire, or explosion hazard when suspended in air or the process-specific oxidizing medium over a range of concentrations. (CMD-CMM)

3.3.15.2* Combustible Metal Particulate. See 3.3.15.1

3.3.15.3* Metal Dust. Metal Particulate resulting from a solid state secondary processing operation. (CMD-CMM).

3.3.16* Combustible Particulate Solid. Any solid material composed of distinct particles, regardless of size, or handled in the facility, has the potential to produce combustible dust. (CMD-FUN)

Ambient-style dust collection can pose serious risks when it comes to handling titanium dust. A simple search on "titanium dust cloud in machine shops" reveals the critical nature of airborne titanium particles. These particles are highly pyrophoric, meaning they can ignite spontaneously upon contact with air, potentially leading to a powerful explosion triggered by even a minor spark or heat source, including static electricity. Therefore, stringent safety protocols are essential when dealing with titanium dust in a machine shop setting. Titanium can affect you when inhaled. Contact can irritate the skin and eyes. Inhaling Titanium can irritate the nose, throat, and lungs. Titanium powder is FLAMMABLE and SPONTANEOUSLY COMBUSTIBLE.

Titanium dust has a Kst value exceeding 300, far surpassing the explosivity level of polyurethane dust at 156 Kst. Despite these dangers, it's concerning to observe the use of ceiling-mounted Ambient Dust Collector systems in machine shops to manage titanium dust plumes. These installations are ill-suited for capturing explosive dust due to numerous inherent limitations.

We can guide you through the requirements of NFPA 660 (formerly 484) in finding the Dust Collection solution that is the most effective and productive. Conductive metal dusts are hazardous and they need expert analysis so that the correct solution is applied.

NFPA 660-Compliant Vacuums for ST1 Dusts in ORDLOC. 3rd Party Certified Explosion-Proof Vacuums for HAZLOC

According to NFPA 660 (page 660-35) it needs to meet the following best-practice build criteria:

8.4.2.2.1.7* For portable vacuum cleaners used with combustible dusts having a minimum ignition energy less than 30 mJ, the path to ground shall be verified prior to use after each movement or new connection, or both.

8.4.2.2.1.8* Portable vacuum cleaners that meet the following minimum requirements shall be permitted to be used to collect combustible particulate solids in unclassified locations:

(1) Materials of construction shall comply with 9.6.6.1.

(2) Hoses shall be conductive or static dissipative.

(3) All conductive and static dissipative components, including wands and attachments, shall be bonded and grounded.

(4) The fan or blower shall be on the clean side of the primary filtration media or wet separation chamber.

(5) The vacuum cleaner shall not be operated without filter media in place.

(6) Electrical motors shall not be located on the dirty side of the primary filtration media or wet separation chamber unless listed for Class II or Class III, Division 1, as appropriate, or Zone 20 or Zone 21 locations.

(7)* Where liquids or wet materials are picked up by the vacuum cleaner, paper filter elements shall not be used.

An Explosion-Proof Vacuum System is a vacuum system that is capable of preventing the ignition of a specified gas or vapor and operates at such an external temperature that a surrounding flammable atmosphere will not be ignited. A Nationally Recognized Testing Lab (NRTL) must certify that a vacuum system is explosion-proof.

8.4.2.2.1.8* Portable vacuum cleaners that meet the following minimum requirements shall be permitted to be used to collect combustible particulate solids in unclassified locations:

(1) Materials of construction shall comply with 9.6.6.1.

(2) Hoses shall be conductive or static dissipative.

(3) All conductive and static dissipative components, including wands and attachments, shall be bonded and grounded.

(4) The fan or blower shall be on the clean side of the primary filtration media or wet separation chamber.

(5) The vacuum cleaner shall not be operated without filter media in place.

(6) Electrical motors shall not be located on the dirty side of the primary filtration media or wet separation chamber unless listed for Class II or Class III, Division 1, as appropriate, or Zone 20 or Zone 21 locations.

(7)* Where liquids or wet materials are picked up by the vacuum cleaner, paper filter elements shall not be used.

3rd Party Explosion Proof Vacuums for use in areas that are:

Div 1 - Groups D and in Class II -Div 1 - Groups F & G Hazardous Locations as defined in the National Electrical Code (NFPA 70). A certified Class II – Div 1 - Group E version is also available.

Do I need a Certified Vacuum for Small Quantities of Conductive Metal Dust in ORDLOC?

Yes. Regardless of whether ORDLOC or HAZLOC, NFPA 660 Chapter 8 Combustible Metals states the following:

NFPA 660 Portable Vacuum Cleaners - Explosive Metal Dusts:

“The use of portable vacuum cleaners shall comply with 22.8.4.2.2. (B)*Due to the inherent hazards associated with portable electric vacuum cleaning systems, the equipment used for cleaning shall be identified for use in Class II, Group E atmosphere.”

We recommend Tiger-Vac® EXP1-5 (4W) RE HEPA and EXP1-20L (DT) RE HEPA (MFS) for residual cleanup of metal powders in ORDLOC and HAZLOC within NFPA stated volumes.

NFPA 660 Chapter 8, 660-35

8.4.2.2.1.9 Portable air-operated vacuum cleaners that meet the following minimum requirements shall be permitted to be used to collect combustible particulate solids in electrically hazardous (classified) area, provided the following are met:

(1) Materials of construction comply with 9.6.6.1.

(2) Hoses are conductive or static dissipative

(3) All conductive or static dissipative components, including wands and attachments, are bonded and grounded.

(4) Where liquids or wet materials are picked up by the vacuum cleaner, paper filter elements are not used.

(5)* The design of the vacuum cleaner is suitable for use in a hazardous (classified) location.

8.4.2.2.1.10* In combustible dust hazardous (classified) locations, vacuum cleaners shall be listed for combustible dust (hazardous) locations.

An Intrinsically Safe Vacuum is one that operates with no moving parts and no electrical parts. The power is supplied by compressed air that is fed into a tapered restriction, also called a “venturi”. Intrinsically safe vacuums are made from non-sparking metals like stainless steel and aluminum. Mild steel is not suitable as it can create a spark when a nut or a screw is vacuumed. It will create a spark when it hits the wall of the vacuum dirt-bin.

Click HERE for more information on our Intrinsically Safe Air Powered Vacuums

Designed for hands-free operation making it ideal for production and robotic cell use. Highly portable and ergonomic XP dust collector for collection of ST1 XP Dust for batching and pouring. Built in Italy, cleverly designed, small footprint, and very easy to maintain. Parts and filters are always on hand. Portable units and arms are usually in stock for immediate shipment.

3rd party certified for use in NFPA classified zones | HAZLOC.

The 600 and 1200 CFM portable dust collectors are fully certified explosion proof for use in hazardous locations as designated by NFPA recommended guidelines and implemented by NRTL.

Per NFPA 660: “All conductive or static dissipative components, including wands and attachments, are bonded and grounded”.

Our range of industrial vacuum hoses includes static-resistant hoses that are Ideal for use with Explosion-Proof Vacuums in NFPA Class I, Div 1, Group D and Class II, Div 1, Groups E, F, and G environments.

Click HERE for more information.

Per NFPA 660: “All conductive or static dissipative components, including wands and attachments, are bonded and grounded”.

Our vacuum tools are impregnated with conductive resins to automatically dissipate static before it happens. .

Ideal for use with Explosion-Proof Vacuums in NFPA Class I, Div 1, Group D and Class II, Div 1, Groups E, F, and G environments.

Click HERE to see our vacuum Tools and Accessories Brochure

In applications where airborne flammable vapors and highly explosive dusts exist, the addition of a retractable grounding reel provides an additional layer of protection.

Per NFPA 660: “All conductive or static dissipative components, including wands and attachments, are bonded and grounded”.

Accessories for all kinds of applications

Air Powered Industrial Vacuums that have no moving parts and no electrical parts. Non-sparking and dissipative construction. FDA Approved materials.

The Enclosure creates a Negative Pressure Zone for better capture

A bolt-on plenum can be added for trapping of VOC and hexavalent chromium

Cabinet-Style Dust Collector for multiple operators producing dust at one time.

Designed to safely capture flammable paint vapors and other fumes that need special filtration

For plastic and paint odor source elimination by arm capture and carbon scrubbing of odors

Capturing powders containing WALOCEL™ MW 15000 PFV Methyl Hydroxyethyl Cellulose at the source

A major plastics manufacturer experienced heavy odors from mixing powders containing WALOCEL™ MW 15000 PFV Methyl Hydroxyethyl Cellulose.

Our team suggested the PDB-VOC source capture collector. The dual 4" ducting collar version allows our client to connect static-dissipative flex ducts directly to the dual 4" pickup points on the mixer, ensuring a completely sealed source capture.

Our experiments demonstrated that the most effective results were obtained when a combination of 4mm potassium permanganate pellets and 4mm activated carbon was used. The PDB-VOC Collector accommodates up to three 24x24x3" carbon cells, each capable of holding 28 lbs. of absorption media. This arrangement ensures thorough capture of the targeted powders, significantly enhancing the company's operational efficiency.

The plant manager expressed great satisfaction with the PDB-VOC Collector, noting its effectiveness in improving their processes, which led to the recent purchase of a second unit.

The XM Torch provides automatic suction of fumes from the torch as soon as you start welding.

Industrial vacuums with high temperature components for safe and sanitary cleaning of ovens and food preparation areas.

Range of HEPA industrial vacuums equipped with Longopac collection bag, ideal to safely collect any kind of very fine and toxic dust.

Pre-Separators can be used in all applications where the extracted material is coarse or voluminous.